Printing Plate Verification System R107

1. Product Introduction

Rosetta R107 printing plate verification system is designed to detect any errors and defects on printing plate by examining the initial print sample, before mass printing production.

It is powered by Rosetta computer vision algorithms and artificial intelligence, runs fast and reliably, significantly improving print plate proofreading efficiency, accuracy and saving human labor cost.

2. Current Manual Inspection and Its Disadvantages

Customer demand: Print plate proofread and initial sample inspection in automatic way instead of human check.

Disadvantages with human manual inspection

Inspector will suffer from visual fatigue after hours of visual checking on character intensive content, therefore manual

inspection quality is not reliable.

Manual inspection costs longer time and more human labor, especially for small batch multi-variety printing.

Manual inspection cannot recognize any foreign languages which the inspector does not know and cannot verify the

readability of barcodes.

3. Rosetta’s Solution for Printing Plate Inspection

Hardware

Apply CIS camera mounted on high precision motion platform, scan the printed sample, and capture high resolution image of the print content.

Software Server

Build up inspection template based on layout analysis algorithm after automatic analysis of the input print plate file.

Apply defect detection algorithm and recognize the defects and their

position, then send signal for next step operation.

Rosetta R107 is a perfect combination of smart algorithm and advanced optical hardware.

4. Main Functions

Range of Application

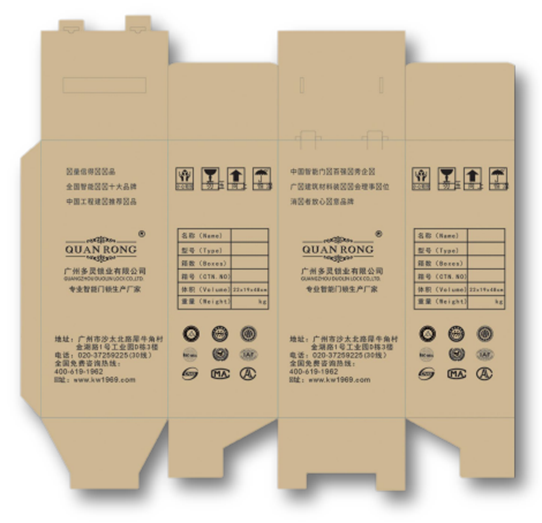

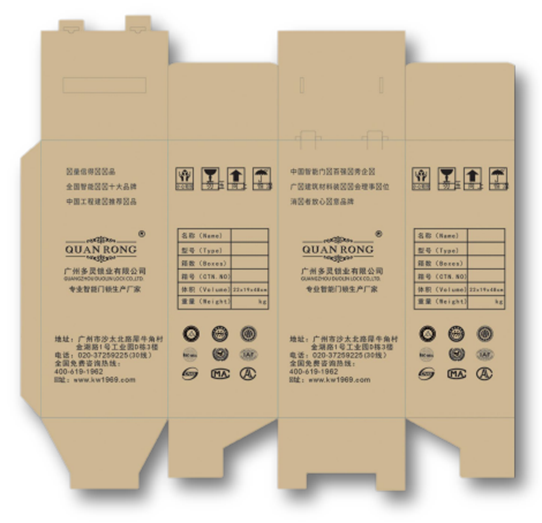

Single color and multi-color printed corrugated boxes

Supported Inspection Content

Text, number, one-dimensional code, two-dimensional

code, table, graphic, pattern.

Detectable Defect Types

Print error, print incomplete, print missing, print deviation.

Supported Readability

Chinese / English text, number, one-dimensional code, and

two-dimensional code.

Supported input File Format

PDF or other regular format, to be input to the software server.

5. Main Technical Specs

|

Inspection Accuracy |

0.5mm |

|

Largest compatible cardboard size |

2400*1200mm |

|

Cycle time |

< 5 seconds |