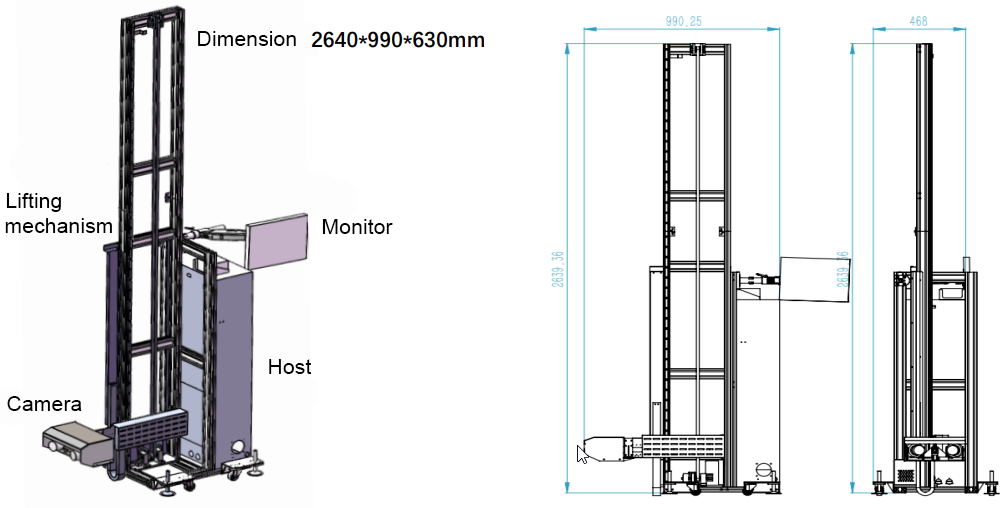

Optical Corrugated Sheet Counter R105

1. Equipment Introduction

1. Introduction

Rosetta R105 uses latest video imaging technology to recognize and count the quantity of corrugated sheets in a stack. A mounted camera will scan the stack from bottom to top and then send images back to the host where Rosetta server software analyzes the image data, recognizing pallets bottom and top automatically, detecting and eliminating interferences, and deliver accurate count result on the screen.

2. Current Inspection Situation in Corrugated Industry

(1) Corrugated sheets are sold based on quantity, so quantity count is a basic management.

(2) Quantity discrepancy could occur in production, warehousing or shipping, and hard to track back.

(3) Mannual count is troublesome and time costful, and mannual counting is not accurate nor reliable.

2. Technical Specifications

1. Main Technical Specs

Stack height: Maximum 2000mm

Speed of Scanning 100cm/sec.

Focus Range: 300~500mm

Calculation Time 5-10 sec.

Counting accuracy: >99.99%

Remote access Yes, for service, parameters changes, upgrades, etc.

Software update Free of cost, during lifetime

Machine dimensions 2640mm * 990mm * 630mm

Machine Weight 70 kgs

Warranty Limited 1-year warranty on all parts

2. Supported Flute Types

All regular flute types except F.

Special flute type can be inspected by our custom development.

3. Inspection principle and characteristics

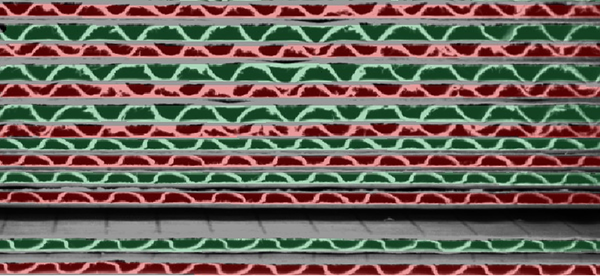

1. Inspection Principle

Through CCD visual photography, the side end image of corrugated cardboard is obtained, and then each corrugated layer is recognized based on deep learning algorithm, and then the number of corrugates is converted to the number of cardboard sheets.

2. Software and algorithm features

Equipped with high-resolution auto-focusing industrial camera.

Universal algorithm recognizes most flute types.

Automatically recognize the pallet and top of the stack, .

Automatically overcome the interferences by gaps between sheets, unevenness in stack laying and fragments.

Equipped with a printer which print labels showing count result.

A USB interface slot for data sharing.

Easy to use, one touch button to start.

4. Technical Advantage

1. Anti-unevenness

Phenomenon: It is inevitable there are some unevenness in the corrugated sheet stack, which might influence imaging and calculation accuracy.

Solution: Rosetta carried out imaging optimization and algorithm optimization. As long as the corrugated sheets are visible, they can be counted precisely.

2. Anti-fragments & damage

Phenomenon: There are occasionally some fragments or damages on the corrugated cardboard side ends, which might influence image capture recognition and calculation accuracy.

Solution: Rosetta camera uses wider visual field and multiple scan paths to overcome the interferences by fragments and damages, to ensure accurate counting.

5. Application Site

6. Installation Location

Factory - Production end

Usually a label showing quantity information is sticked on each stack. The quantity information is from the cutting cycles which is not always equal to real sheets numbers. This equipment can be installed here to correct the quantity immediately.

Factory - Shipping operation counter

Shipping quantity is used for business trading purpose and any discrepancy will arise disputes. This equipment can be installed before shipment loading, to obtain exact quantity for shipment records and future tracebility.

Factory - Warehouse

Shipment inspection: Corrugated cartons factory receive corrugated sheets and need to count the real quantity. This equipment can meet this requirement.

Inventory checking: Regular checking of inventory, this equipment is needed for real count.

7. Application Vedio