AOI Label Quality Inspection in Medical Equipment Industry

1. Customer Condition

1. Customer Introduction

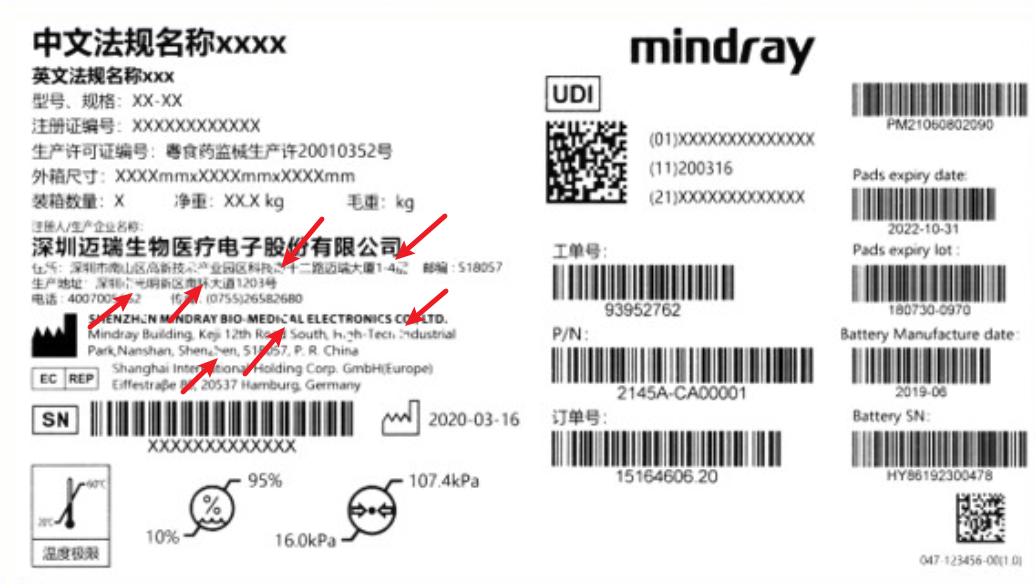

Customer is a a leading high tech medical equipment manufacturer. There are two Zebra label printers working in packaging line. One worker is needed for each printer to take care of printing and mannual label inspection.

2. Current Inspection Condition

(1) Every label must be inspected to ensure 100% compliance.

(2) Some hospital uses low end bar code scanner, and fail to read some labels which result in shipment reject.

3. Customer Inspection Requirement

(1) One-dimentional and two-dimensional barcode readability

(2) Label defects detection

(3) Data verification

2. After Using R210 Label Inspection System

1. Labor cost saved

Before the R210 system is applied, there are total 2 workers for 2 printers at a 8-hour shift.

After applying the R210 system, only one worker is capable of taking care of two printers at a 8-hour shift.

Human labor is saved 50%

2. Print quality is improved

The R210 system detect the defected labels without disturbing printer speed.

Label defect example - print missings.

3. Labelling output is increased

The R210 system runs high speed inspection on labels, and helps the printer decresed suspend time, thus increased the output of the packaging line.